The Importance of Quality and Testing Bolting Applications in Construction

Although many believe that large equipment, steel and wood are the most significant parts of a steel construction project, those in the trade know that the most essential parts are the bolts and nuts. Materials for a construction job must be durable and strong, and equipment must perform at high efficiency, but without fasteners holding everything together there wouldn’t be any skyscrapers, bridges, wind towers or football stadiums. The construction industry relies on bolts and nuts in every project, making quality a crucial aspect.

Safety First

Using high-quality bolts and nuts in every construction project will help avoid hazardous consequences. If the bolts and nuts are made from inferior materials or are manufactured cheaply, the structure can become unsafe. Damaged structures, bridges and large construction projects due to inferior parts or rusted and cracked bolts are just some of the issues that can occur and put everyone who use them at risk.

Underlying Factors

When tightening a nut, a multitude of forces are overcome, including the friction between the nut thread and bolt thread, the tension in the bolt, and the friction between the nut and the washer or the outer ply of the connection. This can be problematic as it is unsure how much of the resistance to turning in the wrench comes from each of the forces.

The coefficient of friction in the threads and between the nut and the surface it is turning against depends on any number of things, most of which cannot be accurately measured. These include the finest details of the thread geometry, the lubrication and cleanliness of the bolt and the nut, and the surface conditions of the washer or outer ply of the connection. Knowing how much of the torque applied has gone towards inducing tension in the bolt is crucial. Studies have shown that the amount of torque required to produce a given amount of tension can vary by as much as 40%.

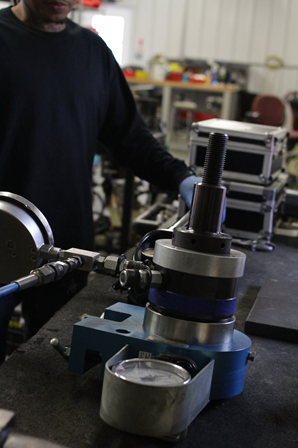

These uncertainties make using a tension-indicating device when we install high-strength bolts a necessity. This is almost always the Skidmore-Wilhelm Bolt Tension Indicator. This device measures the tension in the bolt by measuring the hydraulic pressure in a cell that is squeezed when the nut is tightened. It can be used to verify the tension induced in a bolt by any tightening method, and is required for all high-strength bolt applications designed to follow the AISC code or any of its derivatives.

Next to measuring the tension of the bolt, tightening the bolt to the exact required level is at the top of the list. Bolts shouldn’t be loose to where the joint is not properly kept together and shouldn’t be too tight as the bolt can lose its elastic property and no longer spring back. A prefect bolting is always needed.

Helpful Tip: Unsure if you are using the correct torque tool for your bolting application? Aztec Bolting Services has a variety of torque wrenches and experts to help you understand their capabilities.

To make the work on your construction job more productive, safer and easier to perform, effective bolting is essential. This can be achieved by ensuring the quality is up to standards, testing the tension of the bolts, and tightening the bolt to the exact required level.